Compressed Air Driven Liquid Gas Booster Pump-DGG/DGGD Series

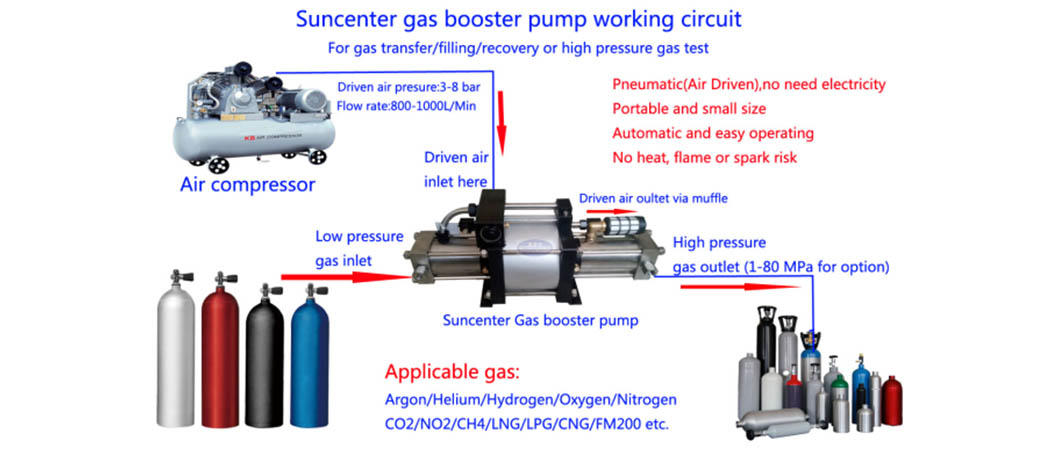

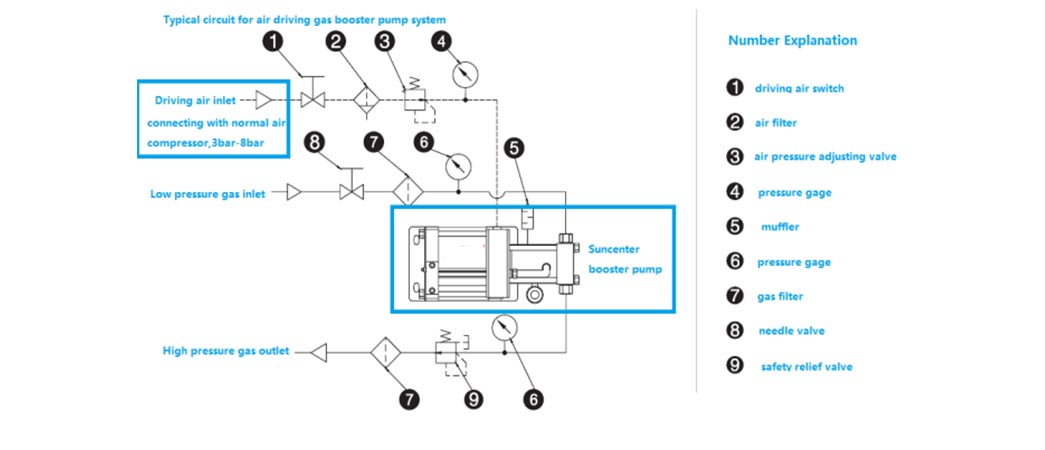

SUNCENTER pumps are air driven at a drive air pressure of 2 to 10bar (29 to145 psi) by the normal air compressor. Basically the principle of operation is similar to a reciprocating amplifier where control of the piston at the end position is regulated by a pilot operated 4/2 way valve.

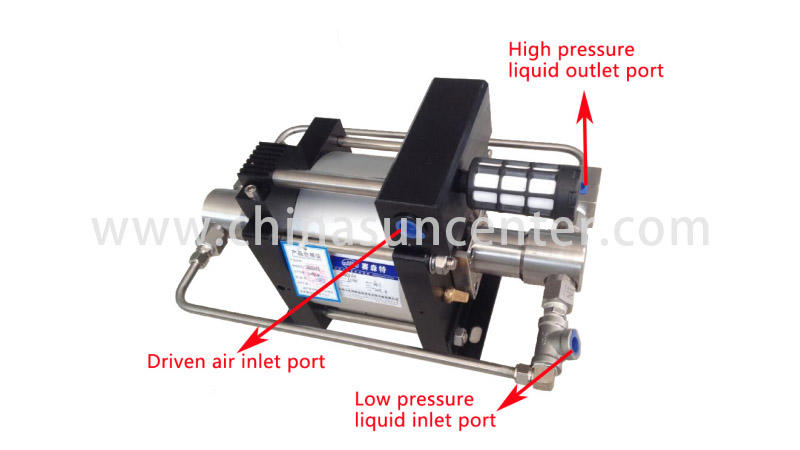

Suncenter pumps feature a large air piston joint to a smaller diameter plunger. The pressure ratio is the difference of these two areas and is the method of determining maximum outlet pressure. Higher pressures obtained by using higher pressure ratios.Suncenter model numbers reflect the pumps nominal pressure ratios, while the technical data indicates exact ratios. The outlet pressure is easily to set through a simple air regulator. By multiplying the pressure ratio by the available shop air pressure, the nominal outlet pressure can be calculated.

DGG Series Liquid Gas Booster Pumps

◪ DGG Series Liquid Gas Booster Pumps

Model | Pressure Boost Ratio | Driven air pressure PL | Formula to calculate outlet pressure | MAX Outlet | Liquid inlet Connection | Liquid outlet Connection | MAX Flow (L/min) |

DGG6 | 6:1 | 3-8 bar | 48 | NPT1/2 | NPT1/2 | 29.91 | |

DGG10 | 10:1 | 3-8 bar | 10XPL | 80 | NPT1/2 | NPT1/2 | 18.84 |

DGG16 | 16:1 | 3-8 bar | 16XPL | 128 | NPT1/2 | NPT1/2 | 12.42 |

DGG28 | 28:1 | 3-8 bar | 28XPL | 224 | NPT1/2 | NPT1/2 | 7.11 |

DGG40 | 40:1 | 3-8 bar | 40XPL | 320 | NPT1/2 | NPT1/2 | 4.89 |

DGG64 | 64:1 | 3-8 bar | 64XPL | 512 | NPT1/2 | NPT3/8 | 3.08 |

DGG80 | 80:1 | 3-8 bar | 80XPL | 640 | NPT1/2 | NPT3/8 | 2.44 |

DGG100 | 100:1 | 3-8 bar | 100XPL | 800 | NPT1/2 | NPT3/8 | 1.92 |

DGGD Series Liquid Gas Pumps(Double acting)

◪ DGGD Series Liquid Gas Pumps(Double acting)

Pressure Boost Ratio | Driven air pressure PL | Formula to calculate outlet pressure | MAX Outlet | Liquid inlet Connection | Liquid outlet Connection | MAX Flow (L/min)** | |

DGGD4 | 4:1 | 3-8 bar | 4XPL | 32 | NPT1/2 | NPT1/2 | 70.00 |

DGGD6 | 6:1 | 3-8 bar | 6XPL | 48 | NPT1/2 | NPT1/2 | 48.60 |

DGGD10 | 10:1 | 3-8 bar | 10XPL | 80 | NPT1/2 | NPT1/2 | 30.61 |

DGGD16 | 16:1 | 3-8 bar | 16XPL | 128 | NPT1/2 | NPT1/2 | 19.73 |

DGGD28 | 28:1 | 3-8 bar | 28XPL | 224 | NPT1/2 | NPT1/2 | 11.30 |

DGGD40 | 40:1 | 3-8 bar | 40XPL | 320 | NPT1/2 | NPT3/8 | 7.69 |

DGGD64 | 64:1 | 3-8 bar | 64XPL | 512 | NPT1/2 | NPT3/8 | 4.94 |

DGGD80 | 80:1 | 3-8 bar | 80XPL | 640 | NPT1/2 | NPT3/8 | 3.96 |

DGGD100 | 100:1 | 3-8 bar | 100XPL | 800 | NPT1/2 | NPT3/8 | 3.13 |

Suncenter DLS Series liquid gas filling booster pump system

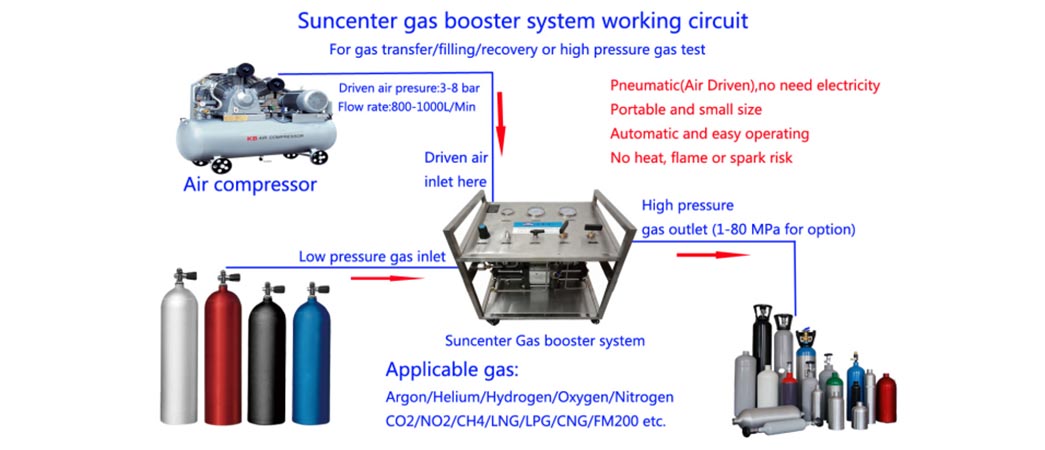

SUNCENTER- Liquid gas filling pump systems are compact and delicacy solution tailored to customer specific requirements with air driven pumps as well as all accessories to be fitted and installed on the frame or in closed cabinet.

To operate this system, the pressure gauges, valves and pressure regulators have to be fitted on panels. The outlet pressure is easily to be set through a simple air regulator. The pump stops automatically when this end pressure is reached and restarts with a slight drop in the outlet pressure or an increase in the air drive pressure.

As the pressure will be generated by means of a pneumatically operated pump,the electric connection will not be necessary. To operate this system, the air driven pump have to be equipped with the air control unit combined filter, pressure-regulating valve, pressure control gauge as well as manual relieve valve. In this operation, the pump will be mounted to the stainless steel tank in the closed cabinet in a compact and space saving manner. Pressure gauges, valves and pressure regulators will be fitted on panel.

DLS liquid gas booster system = liquid gas booster pump+ following valves, gages, and parts

The hottest selling- Model C cabinet picture

◪ The standard gas booster pumps system including following parts:

◪ Air –driven liquid N2O/CO2/NOVEC/Refrigerant gas booster pump

◪ Stainless steel (carbon steel) material cabinet

◪ F.R.L combination for driven air (adjusts air pressure, add lubricating oil and water filter)

◪ Driven air switch (Pump starting switch), driven air pressure gauge

◪ Gas inlet switch, Gas inlet pressure gauge

◪ Gas outlet switch, Gas outlet pressure gauge, unloading valve, interconnecting pipes etc.

◪ And we could also customize it according to clients’ special requirement.

Model | Pressure Ratio | Driven air pressure PL | Formula to calculate outlet pressure | MAX Outlet | Driven | High pressure Outlet port | MAX Flow |

DLS-DGG6 | 6:1 | 3-8 bar | 6XPL | 48 | G 1/2 | NPT/ZG | 29.91 |

DLS-DGG10 | 10:1 | 3-8 bar | 10XPL | 80 | G 1/2 | NPT/ZG | 18.84 |

DLS-DGG16 | 16:1 | 3-8 bar | 16XPL | 128 | G 1/2 | NPT/ZG | 12.42 |

DLS-DGG28 | 28:1 | 3-8 bar | 28XPL | 224 | G 1/2 | NPT/ZG | 7.11 |

DLS-DGG40 | 40:1 | 3-8 bar | 40XPL | 320 | G 1/2 | NPT/ZG | 4.89 |

DLS-DGG64 | 64:1 | 3-8 bar | 64XPL | 512 | G 1/2 | NPT/ZG | 3.08 |

DLS-DGG80 | 80:1 | 3-8 bar | 80XPL | 640 | G 1/2 | NPT/ZG | 2.44 |

DLS-DGG100 | 100:1 | 3-8 bar | 100XPL | 800 | G 1/2 | NPT/ZG | 1.92 |

DLS-DGGD series Liquid gas booster system technical specification

Model | Pressure Ratio | Driven air pressure PL | Formula to calculate outlet pressure | MAX Outlet | Driven | High pressure Outlet port | MAX Flow |

DLS-DGGD4 | 4:1 | 3-8 bar | 4XPL | 32 | G 1/2 | NPT/ZG | 70.00 |

DLS-DGGD6 | 6:1 | 3-8 bar | 6XPL | 48 | G 1/2 | NPT/ZG | 48.60 |

DLS-DGGD10 | 10:1 | 3-8 bar | 10XPL | 80 | G 1/2 | NPT/ZG | 30.61 |

DLS-DGGD16 | 16:1 | 3-8 bar | 16XPL | 128 | G 1/2 | NPT/ZG | 19.73 |

DLS-DGGD28 | 28:1 | 3-8 bar | 28XPL | 224 | G 1/2 | NPT/ZG | 11.30 |

DLS-DGGD40 | 40:1 | 3-8 bar | 40XPL | 320 | G 1/2 | NPT/ZG | 7.69 |

DLS-DGGD64 | 64:1 | 3-8 bar | 64XPL | 512 | G 1/2 | NPT/ZG | 4.94 |

DLS-DGGD80 | 80:1 | 3-8 bar | 80XPL | 640 | G 1/2 | NPT/ZG | 3.96 |

DLS-DGGD100 | 100:1 | 3-8 bar | 100XPL | 800 | G 1/2 | NPT/ZG | 3.13 |

features

※ Compressed Air driven - no electricity required (connect to normal air compressor)

※ In order to extend the lifetime of the pump, the driving air pressure should not be higher than 8 bar

※ No airline lubricator required

※ Wide range of models with different ratios

※ Built-in-cooling on most models

※ Easy to install, operate and maintain

※ Best price / performance ratio

※ No heat, flame or spark risk and explosion proof

※ Automatic pressure holding, whatever the cause of the pressure drop, the Suncenter booster pump will automatically start, keep the loop pressure constant

※ Applicable for various kinds of gas such as N2O/CO2/NOVEC/Refrigerant etc.

※ For liquid gas(liquid+gas mixture) cylinder transfer/filling/recovery

※ For CO2 Fire Extinguisher filling

※ For Supercritical CO2 extraction

video

جميع الحقوق محفوظة © ٢٠٢٥ لشركة دونغقوان صن سنتر لمعدات التحكم بالسوائل المحدودة.