Compressed Air Driven Liquid Gas Booster Pump-DGG/DGGD Series

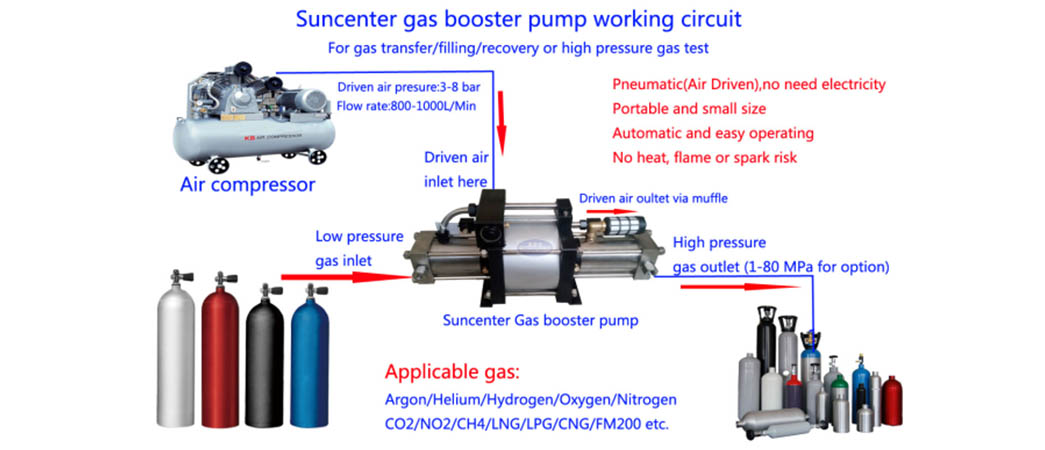

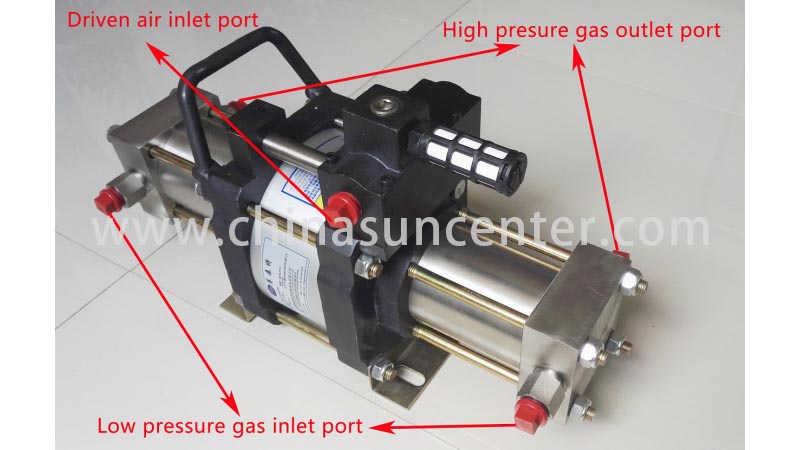

Suncenter Air Driven Gas Boosters provide for pressures up to 80Mpa (11,600 psi). Used for virtually all known gases, these boosters are ideal for increasing gas pressure, transferring high pressure gas, charging cylinders and scavenging. Key features include:

DGGD4 model special gas booster pump

◪ Application: various kinds of liquefying gas such as LNG, LPG, butane, propane, DME, etc

Model | Pressure Boost Ratio | Driven air pressure PL | Formula to calculate outlet pressure | MAX Outlet | Liquid inlet Connection | Liquid outlet Connection | MAX Flow (L/min)** |

DGGD4 | 4:1 | 2bar-8 bar | 4XPL | 8bar-32bar | NPT1/2 | NPT1/2 | 70.00 |

DGGD4 model LPG pump for cylinder transfer working picture

◪ DGGD4 model LPG pump for cylinder transfer working picture

We could also make it into a booster pump station:DGS-DGGD4

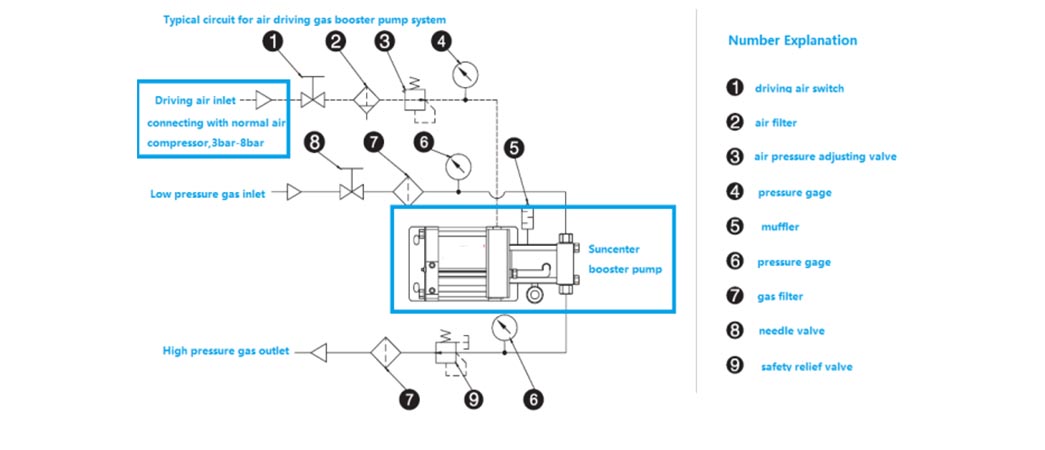

◪ The standard system including following parts:

◪ DGGD4 model gas booster pump

◪ Stainless steel frame cabinet

◪ F.R.L combination for driven air (adjusts air pressure, add lubricating oil and water filter)

◪ Driven air switch (Pump starting switch), driven air pressure gauge

◪ Gas inlet switch, Gas inlet pressure gauge

◪ Gas outlet switch, Gas outlet pressure gauge, unloading valve, interconnecting pipes etc.

◪ And we could also customize it according to clients’ special requirement.

DGS-DGGD4 =Suncenter booster pump(DGGD4)+following valves, gages, and parts

features

※ Compressed Air driven - no electricity required (connect to normal air compressor)

※ In order to extend the lifetime of the pump, the driving air pressure should not be higher than 8 bar

※ No airline lubricator required

※ Hydrocarbon free - separation between air and gas sections

※ Pressures to 80Mpa (11,600 psi)

※ Wide range of models with different ratios

※ Built-in-cooling on most models

※ Easy to install, operate and maintain

※ Best price / performance ratio

※ No heat, flame or spark risk and explosion proof

※ Automatic pressure holding, whatever the cause of the pressure drop, the Suncenter pump will automatically start, keep the loop pressure constant not be higher than 8 bar

video

جميع الحقوق محفوظة © ٢٠٢٥ لشركة دونغقوان صن سنتر لمعدات التحكم بالسوائل المحدودة.