Gas booster pressure test bench

Suncenter - Air/Gas pressure test bench are compact and delicacy solution tailored to customer specific requirements with gas(air) boosters as well as all accessories to be fitted and installed in the frame or a closed cabinet.

To operate this system, the pressure gauges, valves and pressure regulators have to be fitted on panels. The outlet pressure is easily to be set through a simple air regulator.

The pump stops automatically when this end pressure is reached and restarts with a slight drop in the outlet pressure or an increase in the air drive pressure.

Operating pressure up to 80 MPa, for higher pressure, pump with double driven heads is an ideal option.

The hottest selling- Model C frame type cabinet picture

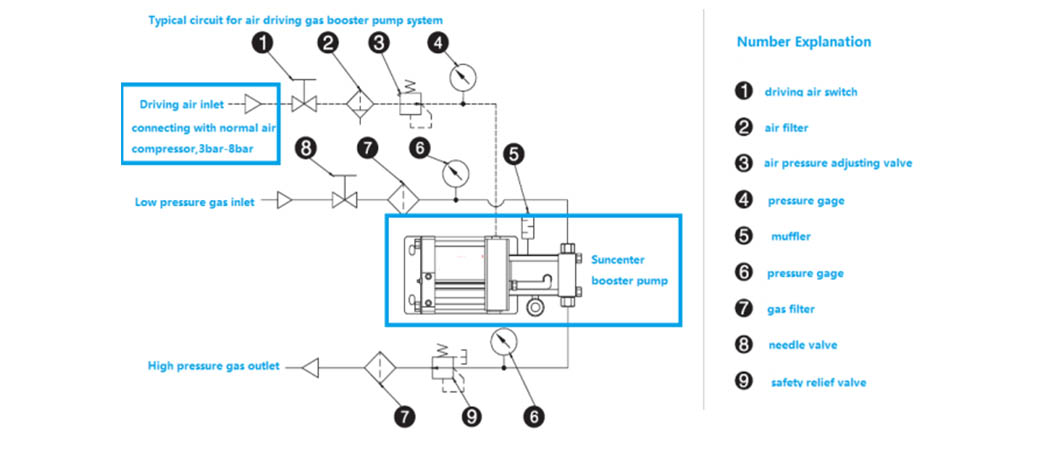

◪ The standard gas booster pumps system including following parts:

◪ Air –driven gas booster pump (DGA/DGD/DGT three series for choosing)

◪ Stainless steel (carbon steel) material cabinet (Three models for choosing)

◪ F.R.L combination for driven air (adjusts air pressure, add lubricating oil and water filter)

◪ Driven air switch (Pump starting switch), driven air pressure gauge

◪ Gas inlet switch, Gas inlet pressure gauge

◪ Gas outlet switch, Gas outlet pressure gauge, unloading valve, interconnecting pipes etc.

◪ And we could also customize it according to clients’ special requirement.

◪ DGS series air/gas pressure test bench with round chart recorder

Model | Pressure boost ratio | Min. gas | Max.gas | Max. gas | Driven air pressure PL | Formula to | Connection: | Max. flow at driven air pressure of 6bar (L/min) |

DGS-DGA02 | 2:1 | 1.0 | 16 | 16 | 2-8 bar | 2X PL | 1/2 / 1/2 | 960 (at PA of 6 bar ) |

DGS-DGA05 | 5:1 | 0 | 40 | 40 | 2-8 bar | 5XPL | 1/2 / 1/2 | 680(at PA of 6 bar ) |

DGS-DGA10 | 10:1 | 3.5 | 80 | 80 | 2-8 bar | 10XPL | 3/8/ 3/8 | 210(at PA of 10 bar ) |

DGS-DGA25 | 25:1 | 7.0 | 200 | 200 | 2-8 bar | 25XPL | 1/4/ 1/4 | 120(at PA of 20 bar ) |

DGS-DGA40 | 40:1 | 10 | 320 | 320 | 2-8 bar | 40XPL | 1/4/ 1/4 | 200(at PA of 40 bar ) |

DGS-DGA60 | 60:1 | 20 | 480 | 480 | 2-8 bar | 60XPL | 1/4/ 1/4 | 180(at PA of 40 bar ) |

DGS-DGA100 | 100:1 | 25 | 800 | 800 | 2-8 bar | 100XPL | 1/4/ M14X1.5 | 136(at PA of 40 bar ) |

DGS-DGA130 | 130:1 | 35 | 800 | 1040 | 2-8 bar | 130XPL | 1/4/ M14X1.5 | 120(at PA of 40 bar ) |

Technical specification for DGS-DGD series

Model | Pressure boost ratio | Min. gas | Max.gas | Max. gas outlet pressure PB (bar) | Driven air pressure PL | Formula to | Connection: | Max. flow at driven air pressure of 6bar (L/min) |

DGS-DGD10 | 10:1 | 3.5 | 80 | 80 | 2-8 bar | 10XPL+ PA | 3/8/3/8 | 410(at PA of 6 bar ) |

DGS-DGD25 | 25:1 | 10 | 200 | 200 | 2-8 bar | 25XPL+ PA | 1/4/1/4 | 396(at PA of 20 bar ) |

DGS-DGD40 | 40:1 | 15 | 320 | 320 | 2-8 bar | 40XPL+ PA | 1/4/1/4 | 320(at PA of 40 bar ) |

DGS-DGD60 | 60:1 | 25 | 480 | 480 | 2-8 bar | 60XPL+ PA | 1/4/1/4 | 215(at PA of 40 bar ) |

DGS-DGD100 | 100:1 | 35 | 800 | 800 | 2-8 bar | 100XPL+ PA | 1/4/M14*1.5 | 300(at PA of 60 bar ) |

Technical specification for DGS-DGT series

Pressure boost ratio | Min. gas | Max.gas | Max. gas | Driven air pressure PL | Formula to | Connection: | Max. flow at driven air pressure of 6bar (L/min) | |

DGS-DGT25 | 25:1 | 0.1 | 10 | 200 | 2-8 bar | 25XPL+3.5XPA | 1/4/ 1/4 | |

DGS-DGT40 | 40:1 | 0.1 | 10 | 320 | 2-8 bar | 40XPL+ 6XPA | 1/4/1/4 | 124(at PA of 8 bar ) |

DGS-DGT10/60 | 10:1/60:1 | 0.1 | 10 | 480 | 2-8 bar | 60XPL+6X PA | 1/4/1/4 | 84(at PA of 8 bar ) |

DGS-DGT25/60 | 25:1/60:1 | 10 | 25 | 480 | 2-8 bar | 60XPL+2.5XPA | 1/4/1/4 | 80(at PA of 15 bar ) |

DGS-DGT100 | 100:1 | 0.1 | 10 | 800 | 2-8 bar | 100XPL+10XPA | 1/4/ M14*1.5 | 63(at PA of 8 bar ) |

video

جميع الحقوق محفوظة © ٢٠٢٥ لشركة دونغقوان صن سنتر لمعدات التحكم بالسوائل المحدودة.